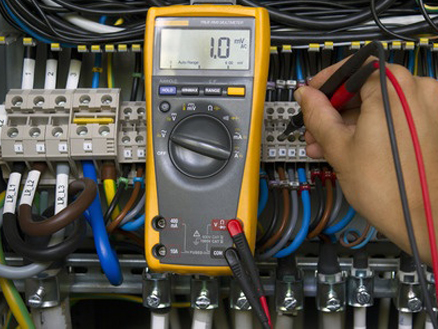

Our company is specialized in the maintenance and retrofit of CNC machine tools. You can trust us for all your needs in support of your CNC machines.

For repairs, calibrations, adjustments, parts, retrofits, safety and security interlocks, training, you can count on our experienced and qualified personnel to meet all your needs.

We have over 25 years of experience in the field of repair and retrofit of CNC machine tools. We are efficient and competent. Whether you need help for a simple service call or you plan to retrofit a machine, we are here to help you and give you full satisfaction.

We train every type of personnel related to your machine tools. We offer all kinds of training courses to optimize operations and improve your maintenance staff. Results are an increase of productivity from your production staff and an overall improved performance for your enterprise. The more your staff knows about the capabilities of the machines the more productive they become.

Share this page!

Last news

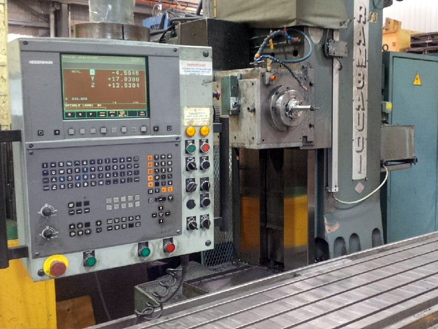

The production of large-sized parts is often very complex and costly, and requires high-tech machines, great precision and reliability to meet customers’ needs. This is exactly what is provided by the solution installed in the workshop at Pedrali Meccanica, where the latest machine purchased (a Soraluce milling machine) was equipped with the CNC 8065 numerical control system by Fagor Automation A successful company: Pedrali Meccanica Pedrali Meccanica, a mechanical engineering firm specialized in the turning and milling of large-sized parts (up to 60 tons), has always been on the cutting edge, thanks to the development work carried out…

Linear encoders in Closed Loop operation on machine tools ensure that thermal errors and other influences of feed mechanisms are fully compensated. This results in especially accurate dimensions and contours starting from a batch size of one. With the aid of animations and an example machining operation, the film “Accuracy on Modern Machine Tools” uses a demonstration unit to illustrate how quickly a recirculating ball screw warms up and what effect even a relatively small temperature increase can have without Closed Loop control. Or would you have thought that only ten traversing movements at 60 m/min could increase temperature of…